TIDDOX Pharmaceutical Wipes play a critical role in contamination control and critical cleaning applications. We offer both sterile and non-sterile wipes to ensure that aseptic conditions are maintained. They are widely used in pharmaceutical manufacturing and production areas, laboratories, and cleanrooms. Pharma Wipes

Filter by price

TIDDOX Delicate Task Wipes | 280 pcs | 21cm x 11cm

Diversey Oxivir TB Wipes Hospital Grade | 160 Wipes | 15.5cm x 17.3cm

Ansell TouchNTuff 92-600 Nitrile Gloves | Green | 100pcs

Ansell TouchNTuff 92-605 Long Cuff Nitrile Gloves | Green | 100 pcs

Bastion ExtraTough Nitrile Gloves | Green | 100 pcs

Bastion Disposable Hair Caps | 100 pcs

White Meltblown Wipes | 150 pcs per box | 43cm x 35cm

Blue Meltblown Degreaser Wipes | 250 pcs per box | 43cm x 35cm

Polycellulose Wipes Roll | 90 pcs | 50cm x 30cm

Recently Viewed Products

Pharmaceutical Wipes for Controlled Environments

Cleanliness and contamination control are essential in pharmaceutical manufacturing, laboratory processes and biotechnology research. Every work surface, instrument and production area must be maintained to strict cleanliness levels to protect product integrity and ensure compliance. TIDDOX supplies a specialised range of pharmaceutical wipes developed for use in controlled environments where consistent performance and material purity are required. These wipes offer low lint behaviour, strong absorbency and reliable compatibility with disinfectants used in sterile and non-sterile cleaning procedures.

TIDDOX pharmaceutical wipes are used across cleanrooms, compounding areas, aseptic processing zones, formulation suites, quality control laboratories and production floors. Each wipe material is designed to minimise particle release and maintain integrity when saturated with alcohols and sanitising agents. Options are available in sterile and non-sterile formats so teams can match wipe selection to cleanroom class, workflow sequence and cleaning protocols.

For precision cleaning of sensitive surfaces, our Polyester Knitted Cleanroom Wipes provide a smooth, low lint finish suitable for stainless steel benches, isolators, glass equipment and electronic components. These continuous filament wipes feature sealed edges, low extractables and solvent compatibility, making them suitable for ISO Class 4 to 8 environments. The 2-Ply Sterile Polyester Knit Wipes offer added liquid retention and durability for aseptic compounding and sterile production and are gamma irradiated and double bagged for controlled entry into clean zones.

Where static dissipation is required, the Anti-Static Polyester Knitted Wipes are manufactured with interwoven carbon yarns to manage static charge on contact. These wipes are used in semiconductor handling, PCB assembly and optical cleaning where static control is essential.

For delicate surfaces such as lenses, display glass and precision instruments, Polyester Nonwoven Wipes offer a soft, binder free construction with a smooth texture. They are hydroentangled rather than chemically bonded, providing strength without leaving residue.

For broader production support spaces, Polyester Cellulose Wipes offer high absorbency and controlled lint levels. These wipes are available in both sterile and non-sterile formats, including Sterile Polyester Cellulose Nonwoven Wipes gamma irradiated to SAL 10⁻⁶ for ISO Class 5 use.

Where removal of oils, lubricants and solvent residues is required, Meltblown Polypropylene Wipes deliver strong absorbency and chemical compatibility. These wipes remain intact when saturated and are commonly used for cleaning equipment surfaces, parts handling and solvent wipe down steps.

For fine particle control and residue removal, Microfibre Nonwoven Wipes and Microfibre Knitted Wipes provide excellent capture efficiency. These wipes lift and retain particles rather than pushing them across the surface, making them suitable for final wipe down and precision polishing in inspection areas and instrument cleaning zones.

Additional options such as Polypropylene Cellulose Wipes and Cotton Nonwoven Wipes provide economical choices for spill absorption and routine sanitation while maintaining low lint performance and solvent compatibility.

Sterile pharmaceutical wipes undergo validated gamma irradiation, are bagged for cleanroom transfer and supplied with batch and sterility documentation. Non-sterile versions are cleanroom processed and packaged to support controlled handling workflows.

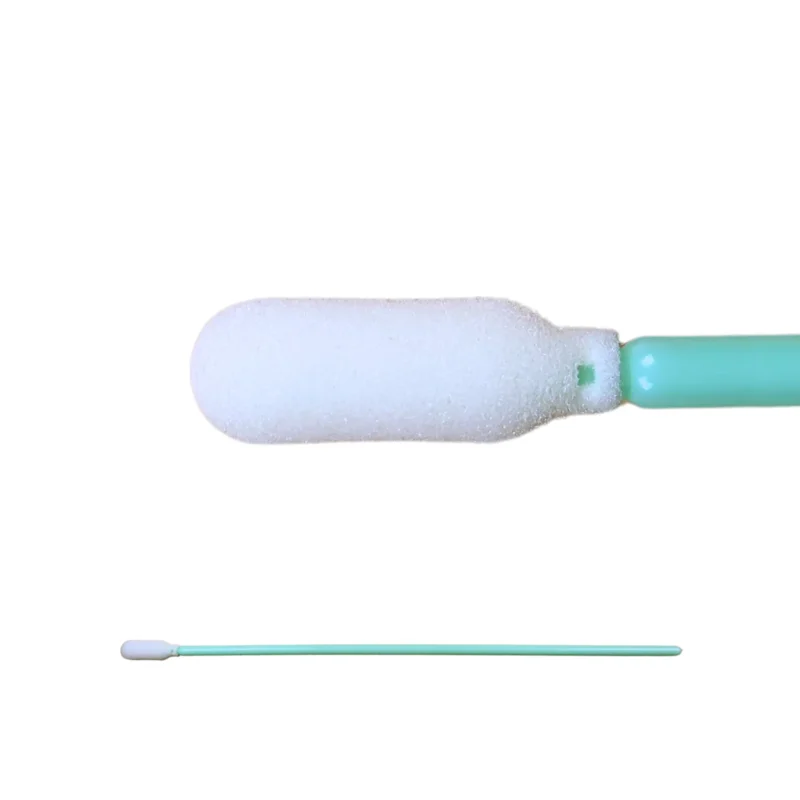

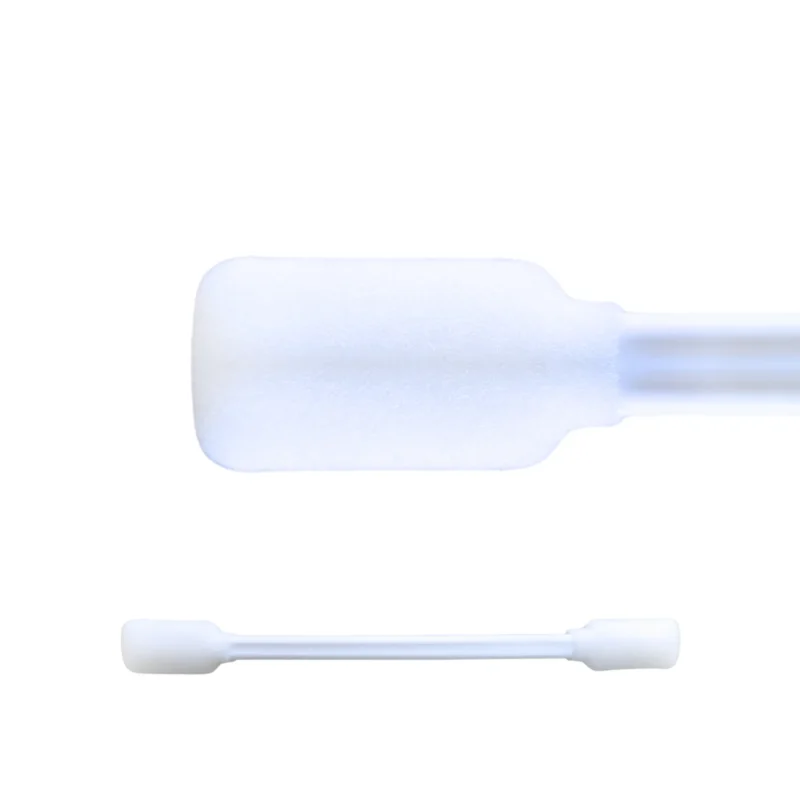

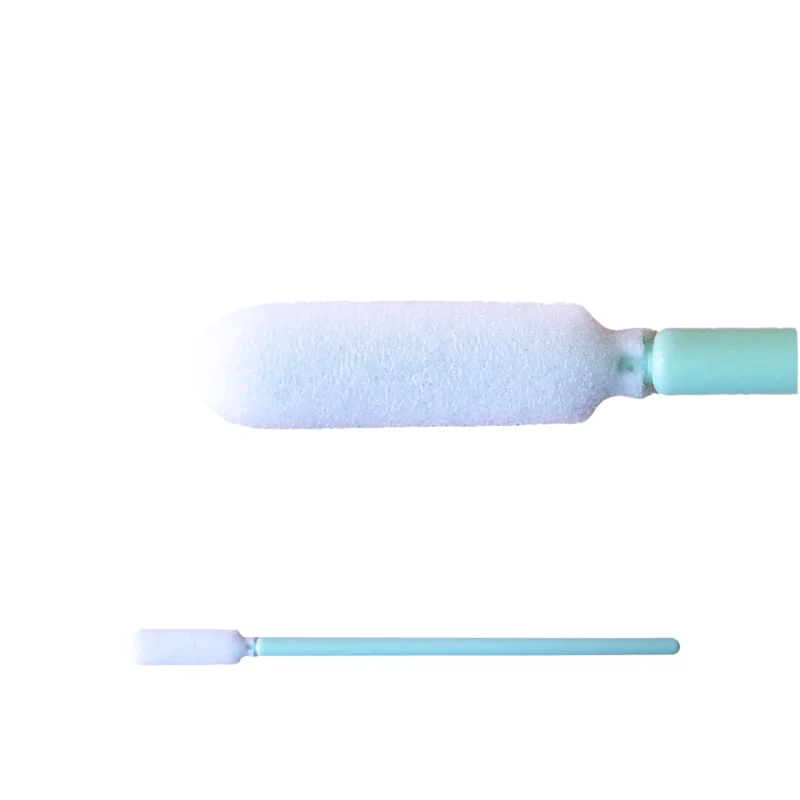

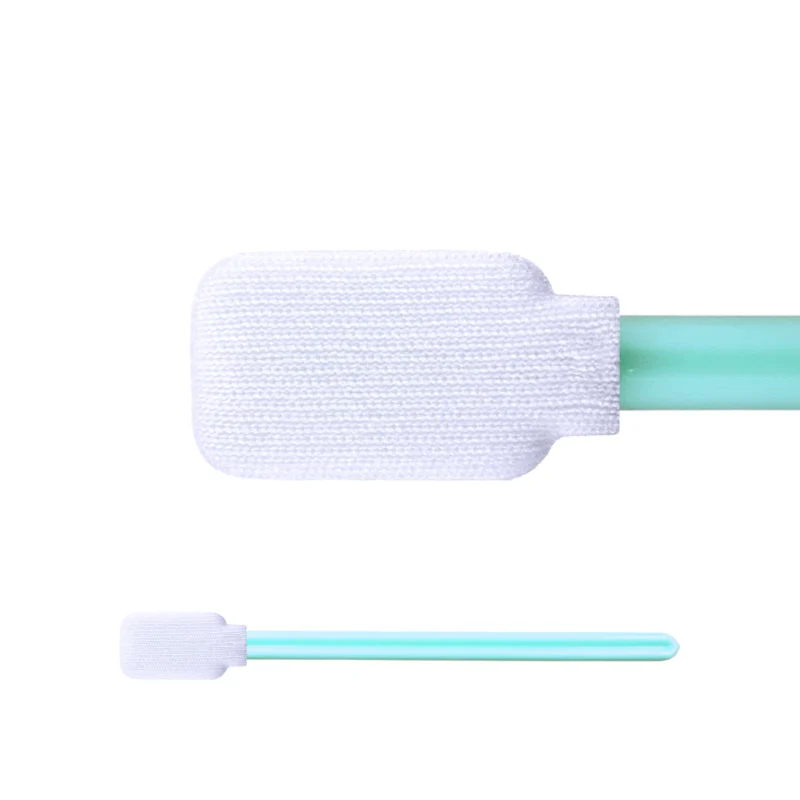

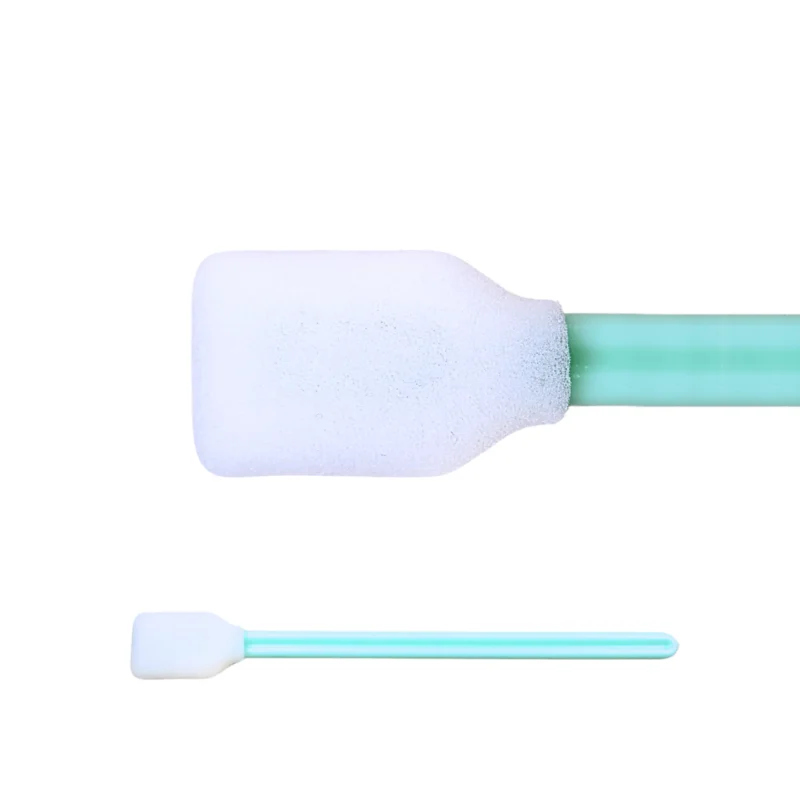

TIDDOX also supplies cleaning swabs for tasks where precise, clean contact is essential. Polyester swabs support contamination sensitive work such as surface analysis and TOC sampling, with laundered low lint heads that are thermally bonded and compatible with IPA and common disinfectants. Long handle and large rectangular options reach recesses or apply even pressure on flat panels. For daily maintenance and delicate parts, foam swabs provide soft, absorbent control with 100 PPI polyurethane heads that lift residues and release solvents evenly. Choose long handle, large rectangular, or flexible head designs to clean joints, channels, and complex features without scratching or transferring adhesives.

TIDDOX works closely with pharmaceutical, biotechnology and medical device facilities to match wipe material, absorbency level and packaging style to the intended task. Formats include flat sheets, perforated rolls, pop up cartons and controlled use dispenser systems.

For support with product selection, samples or supply planning, contact the TIDDOX team.

Frequently Asked Questions

Pharmaceutical wipes are used in cleanrooms, laboratories, compounding areas and manufacturing suites to control contamination, clean equipment surfaces and support sterile workflow practices. They help remove particles, residues and microbial risk from critical production areas.

Sterile wipes are gamma irradiated and supplied with batch certification to support aseptic environments. Non sterile wipes are cleanroom processed and used for controlled cleaning tasks where full sterility is not required.

Loose fibres, particles or extractables can compromise product purity or interfere with analytical work. Low lint and low NVR wipes reduce contamination risk and support compliance with GMP and ISO cleanroom standards.

Knitted polyester wipes are used for highly controlled environments because they shed very few fibres and remain strong when saturated with disinfectants. Microfibre wipes are used when fine particle pickup and residue removal is required.

Yes. Most pharmaceutical wipes are manufactured to be compatible with IPA, ethanol, hydrogen peroxide blends and disinfectants without breaking apart, leaving residue or affecting surface integrity.