ISO Class Cleanroom Wipes

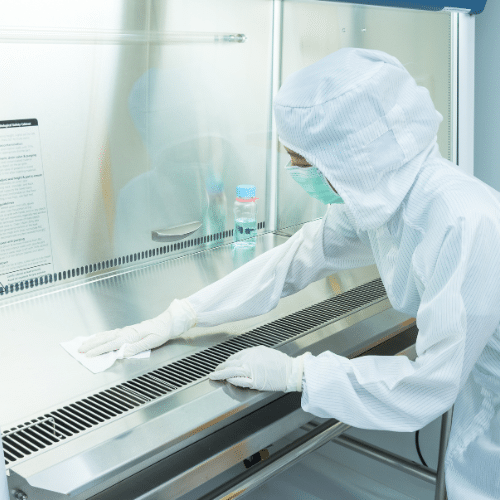

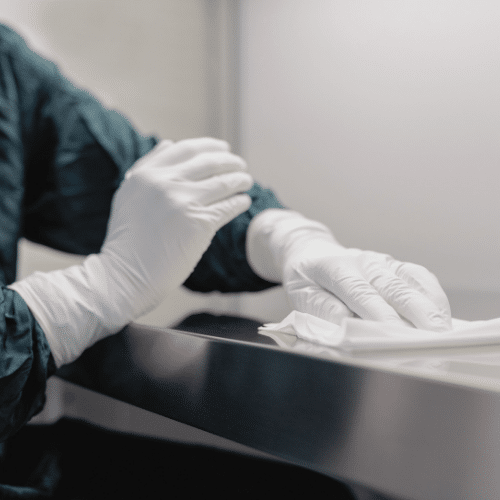

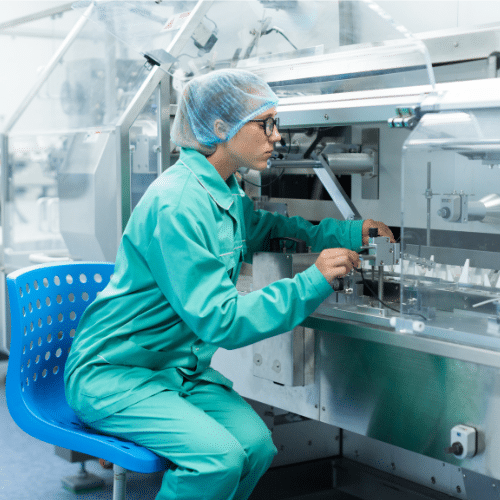

We supply ISO-class cleanroom wipes built to meet the stringent demands of highly controlled environments in industries such as pharmaceuticals, biotechnology, electronics, medical device manufacturing, semiconductors, and healthcare. Cleanrooms rely on extremely low particle counts and tight contamination control, so our cleanroom wipes play a pivotal role in preserving sterility, minimizing particulate shedding, and protecting sensitive processes.

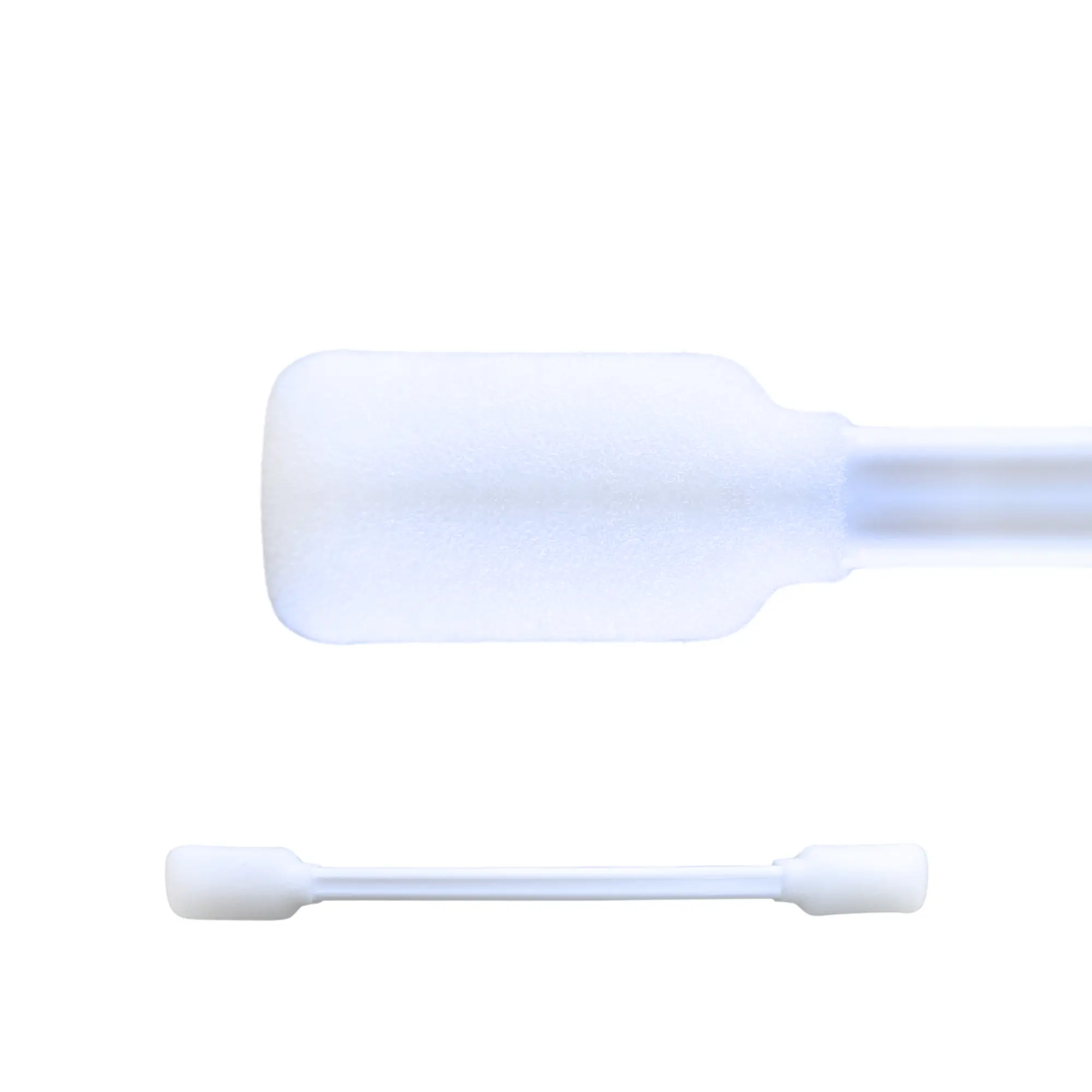

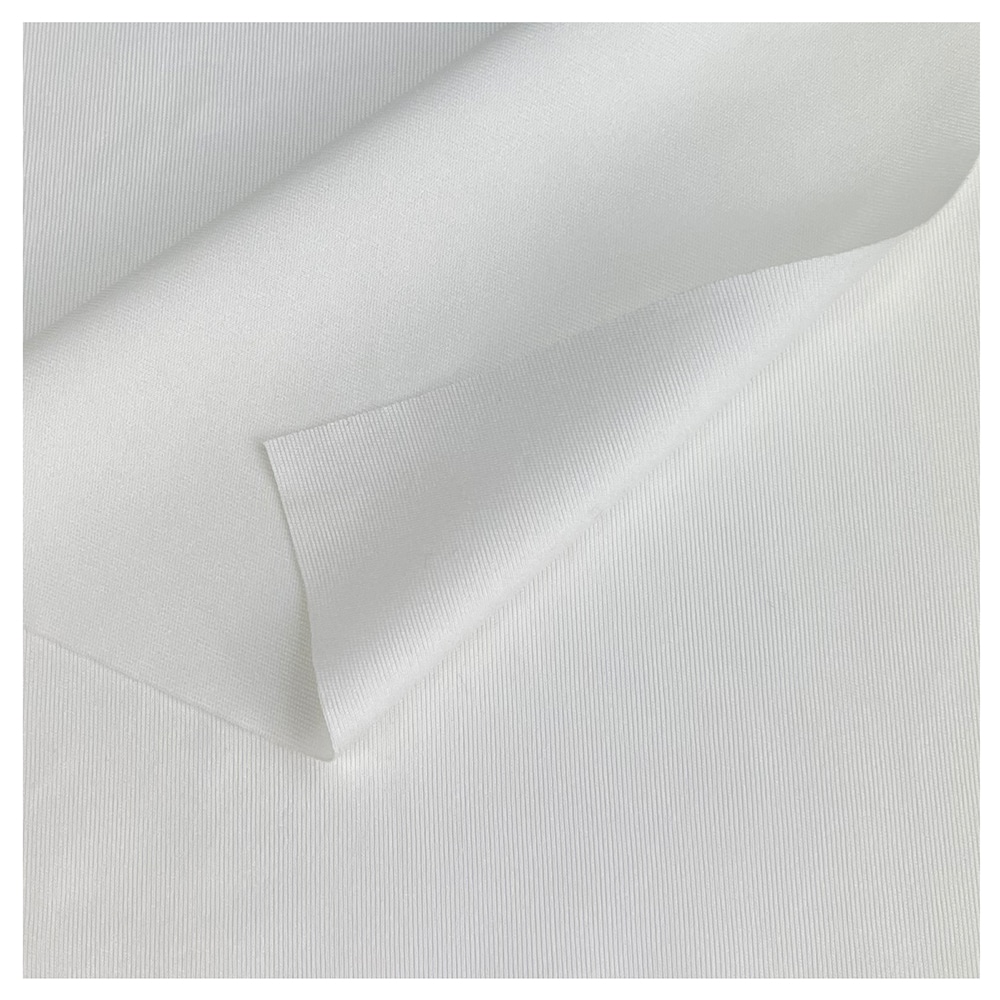

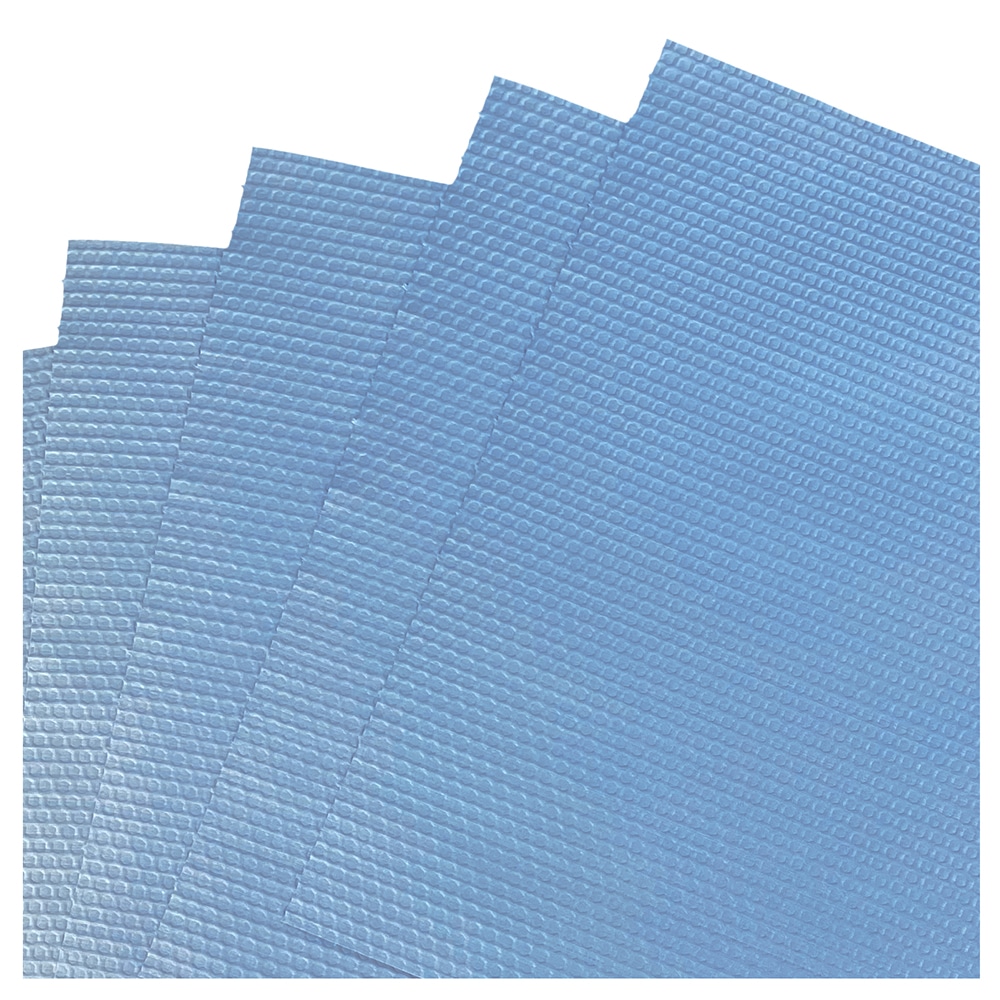

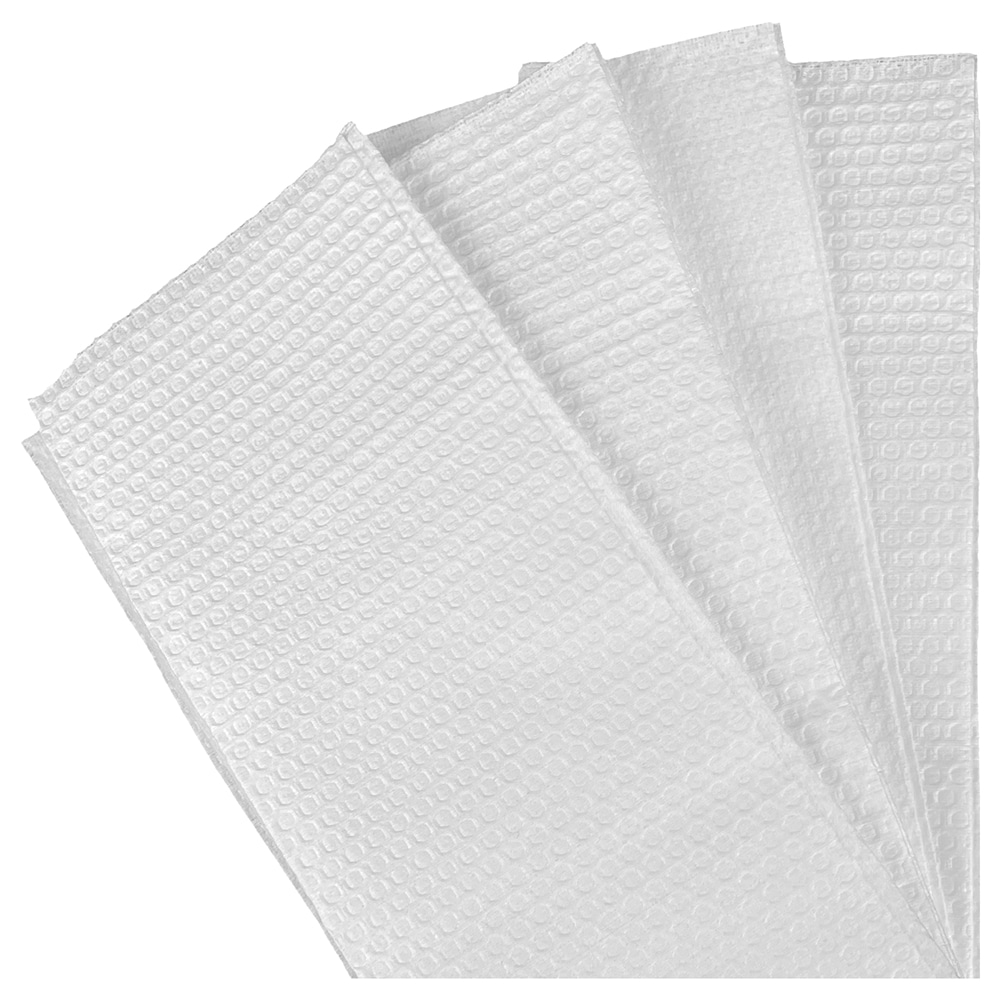

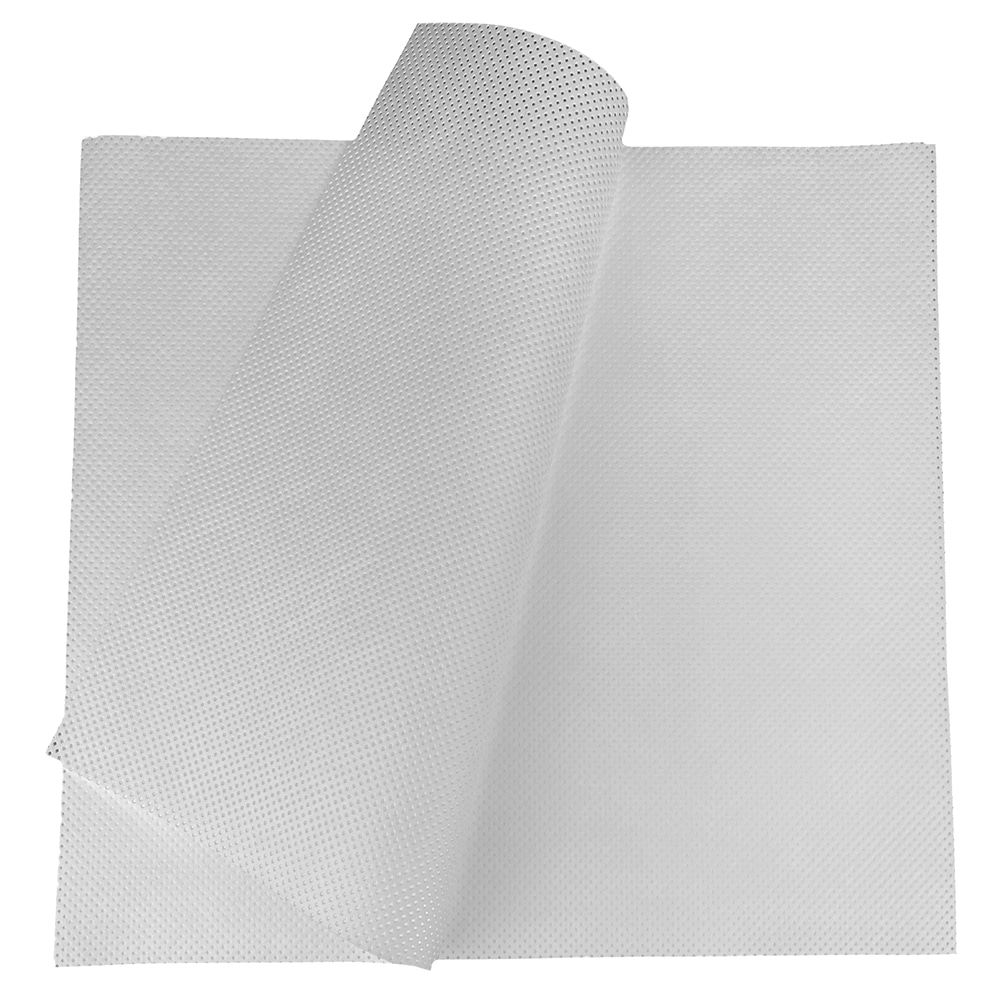

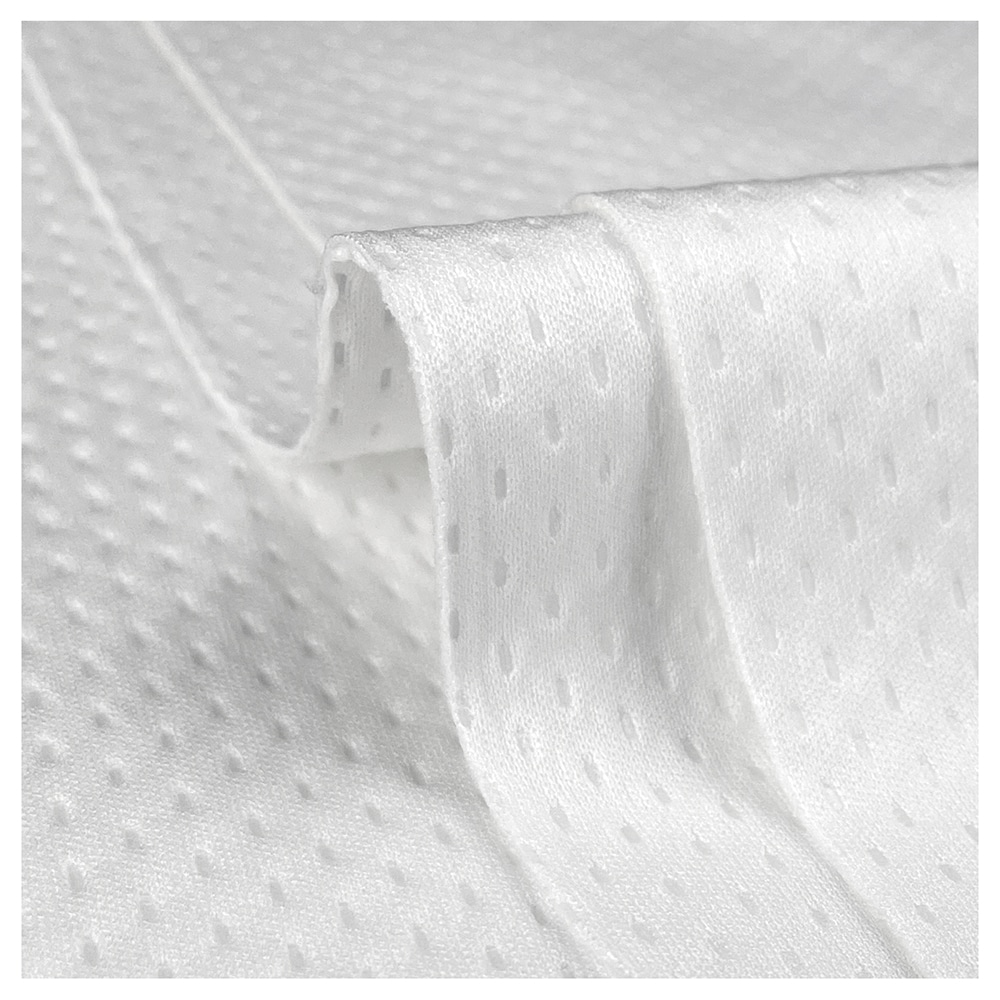

Our ISO-class wipes are engineered to comply with various ISO classifications (e.g., ISO 4 through ISO 8), assuring that the wipes themselves will not introduce contaminants into critical areas. These wipes are fabricated from premium materials that are non-shedding and low-linting, ensuring they do not contribute to airborne particles or fibers during use. To achieve this, we use tightly knitted or laundered continuous-filament polyester fabrics, or polyester/cellulose blends processed with cleanroom techniques. Many are heat-sealed or edge-treated to prevent loose fibers, and some are washed, dried and packaged in controlled cleanroom conditions to further reduce particulates and residues. For example, our “Lint-Free PolySoft Wipes” are double-knit polyester with sealed edges and minimal particle/fiber levels, making them ideal even in strict environments.

Because our wipes are produced with low extractables, we minimize ionic or chemical contaminants — an important attribute in pharmaceutical or semiconductor workflows. We also offer wipes in sterile or non-sterile formats, as needed for aseptic zones, and with various sizes, weights (gsm), and packaging to match the particular ISO class target environment. Standard cleanroom wiping practices (such as unidirectional wiping, controlled humidity, and prewetting) help maximize effectiveness and minimize cross-contamination.

Frequently Asked Questions

What are cleanroom wipes?

Cleanroom wipes are made using special processes to reduce the risk of contamination in controlled areas and critical tasks. These processes include using materials low in lint, with tightly bound or knitted fibres, washing the materials multiple times to remove excess ions and non-volatile residues, packaging the wipes in a cleanroom environment, and may also involve sterilising them to kill off any micro-organisms.

What are cleanroom wipes made of?

To minimise particle or fibre contamination, cleanroom wipes are made from tightly woven or knitted polyester, polypropylene, cellulose or microfibre materials.

What does the ISO class refer to?

The ISO class of a cleanroom refers to the level of cleanliness that it must maintain. The higher the ISO class number, the cleaner the environment needs to be. Regular cleaning with special cleanroom wipes and sterile wipes helps maintain cleanliness and sterility in these critical areas. Cleanrooms are classified based on the maximum allowable number of particles per cubic metre of air, with Class 1 being the cleanest and Class 9 being the least clean.

What is the difference between dry, pre-wetted and sterile cleanroom wipes?

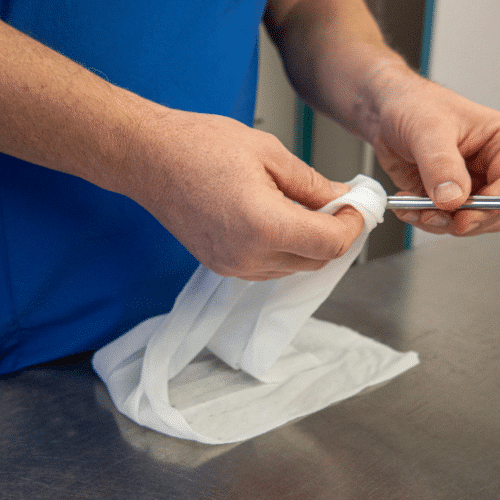

Dry cleanroom wipes come in a clean, unpackaged or clean-packaged state. They are made for general wiping tasks. You can also use them to apply a cleaning or disinfecting solution when needed. Pre-wetted wipes are already saturated with a controlled amount of solvent or cleaning agent (e.g. IPA, sterile water) to save handling steps and reduce contamination risks. Sterile wipes are cleaned using a proven sterilization method, like gamma irradiation. They are packaged to stay sterile until you use them. This makes them ideal for aseptic or critical pharmaceutical zones where sterility must be assured.

How do I choose the right cleanroom wipe material and edge-treatment for my ISO class?

When selecting a cleanroom wipe, several factors matter: the wipe’s material (e.g. polyester, polyester/cellulose blends, foam), its edge treatment (cut, sealed, laser-sealed), and its cleanroom compatibility. For stricter ISO classes (ISO 3–ISO 5), use wipes made of continuous filament polyester. Sealed or laser-cut edges help reduce fiber release. For less critical zones (e.g. Wipes made from poly-cellulose blends or nonwoven materials may be enough for ISO 6 to ISO 8. The right match helps balance cost with performance and ensures you don’t introduce unnecessary particles into your facility.